The Difference between Servo Motor Voltage Stabilizer and Relay Type Voltage Stabilizer

Site Editor

Site EditorIn the field of voltage regulation, servo motor voltage stabilizers and relay type voltage stabilizers are two commonly used devices, each with its own unique characteristics and applications. Understanding the differences between them is crucial for making an appropriate choice based on specific power supply requirements.

Working Principle

The servo motor voltage stabilizer operates based on a precise control mechanism. It continuously monitors the input voltage through an electronic control circuit. When a deviation from the desired voltage level is detected, the control circuit activates a servo motor. This servo motor then drives a carbon brush that moves along the windings of an autotransformer. By changing the position of the carbon brush and thus altering the turns ratio of the autotransformer, the output voltage is adjusted to the set value. This process allows for highly accurate and continuous voltage regulation, ensuring a stable power supply even in the face of significant input voltage fluctuations.

In contrast, the relay type voltage stabilizer functions using a combination of electronic circuits and relays. The electronic circuit constantly compares the input voltage with a reference voltage source. When the input voltage deviates from the reference value, the circuit triggers the appropriate relay. These relays are connected to different taps of a transformer. By switching among these taps, the voltage applied to the load is adjusted. However, this switching process is discrete and not as continuous as in the servo motor voltage stabilizer.

Performance Characteristics

Regarding voltage regulation accuracy, the servo motor voltage stabilizer offers a much higher precision. It can typically maintain the output voltage within ±1% of the set value, even with input voltage variations as large as ±50%. On the other hand, the relay type voltage stabilizer has a relatively lower accuracy, usually in the range of ±5% to ±10%, and it can handle input voltage fluctuations within a narrower range, typically ±15% to ±6%.

The speed of voltage adjustment is another significant difference. The servo motor voltage stabilizer responds rapidly to voltage changes and can adjust the output voltage almost instantaneously without any interruption. In contrast, the relay type voltage stabilizer has a slower response time. When the relays switch, there is a brief moment of voltage interruption, which may affect the operation of some sensitive electrical equipment.

In terms of reliability and durability, the servo motor voltage stabilizer has an edge. It is built with advanced control technologies and high-quality components, providing excellent anti-interference capabilities and long-term stability. The relay type voltage stabilizer, due to the mechanical operation of the relays, may experience issues such as contact wear and oxidation over time. These problems can lead to poor contact, reduced stability, and a shorter service life.

Internal Structure

The servo motor voltage stabilizer consists of several key components. It includes a servo motor, a buck-boost transformer, an autotransformer, a control circuit, and a motor driver. The servo motor, under the control of the driver and circuit, precisely adjusts the autotransformer to regulate the voltage. The buck-boost transformer may be used for further fine-tuning or handling extreme voltage conditions.

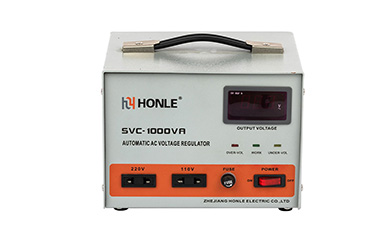

The relay type voltage stabilizer mainly comprises operational amplifiers, rectifier circuits, a microcontroller unit, and relays. The operational amplifiers and microcontroller unit are responsible for comparing the input voltage with the reference and determining when to activate the relays. The rectifier circuit provides the necessary DC power for the electronic components to operate.

The structure of the servo motor voltage stabilizer is more complex and sophisticated due to the need for precise motor control and continuous voltage adjustment mechanisms. The relay type voltage stabilizer has a relatively simpler structure, which also contributes to its lower cost.

Applicable Scenarios

The servo motor voltage stabilizer is well-suited for applications where high voltage accuracy is essential, such as in precision instrument manufacturing, medical equipment operation, and data centers. These environments require a stable and precise power supply to ensure the accurate functioning of sensitive devices and to prevent data loss or equipment damage due to voltage fluctuations.

The relay type voltage stabilizer is more appropriate for situations where the voltage regulation requirements are not as stringent and the load power is relatively small. For example, it can be used for powering common household appliances like refrigerators, televisions, and small power tools. It provides a cost-effective solution for basic voltage stabilization needs in residential and light commercial settings.

Cost and Maintenance

The servo motor voltage stabilizer, with its advanced features and complex construction, generally has a higher manufacturing cost and is sold at a relatively higher price. Additionally, its maintenance requires professional technical knowledge and skills. Servicing may involve tasks such as calibrating the control circuit, checking the motor and its drive components, and replacing worn parts, all of which can be costly.

The relay type voltage stabilizer has a lower cost, making it more accessible for budget-conscious consumers. Its maintenance is relatively simple, mainly focusing on inspecting and replacing the relays when necessary. The cost of relay replacement is usually lower compared to the components in a servo motor voltage stabilizer.

In conclusion, both servo motor voltage stabilizer and relay type voltage stabilizer have their own advantages and disadvantages. The choice between them depends on the specific requirements of the application, including the desired voltage accuracy, load characteristics, budget constraints, and the importance of uninterrupted power supply. By carefully considering these factors, users can select the most suitable voltage stabilizer to ensure the reliable and efficient operation of their electrical systems.